1.pet utomonimawu oyamba

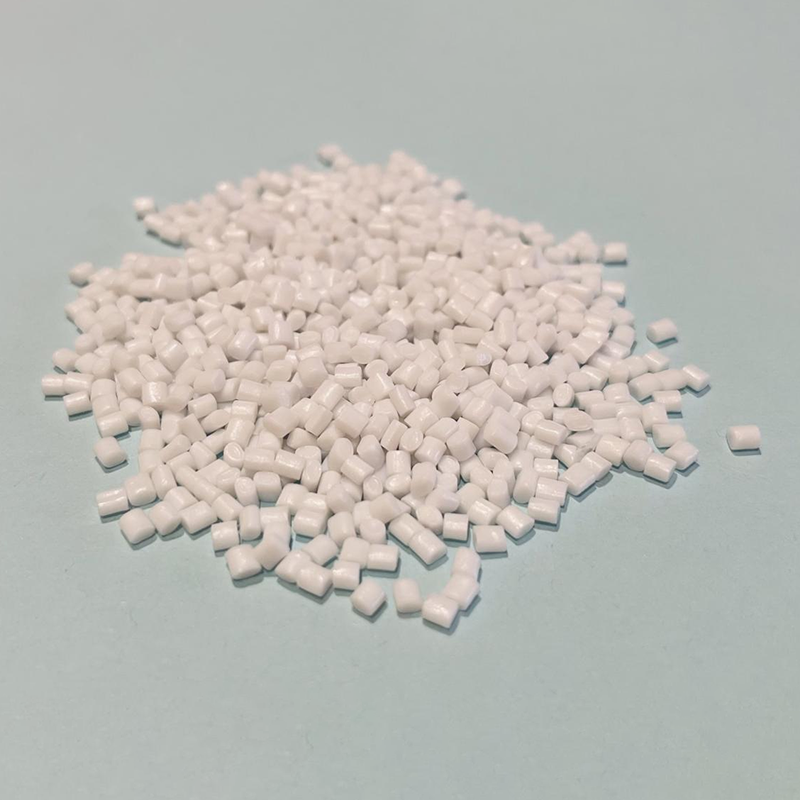

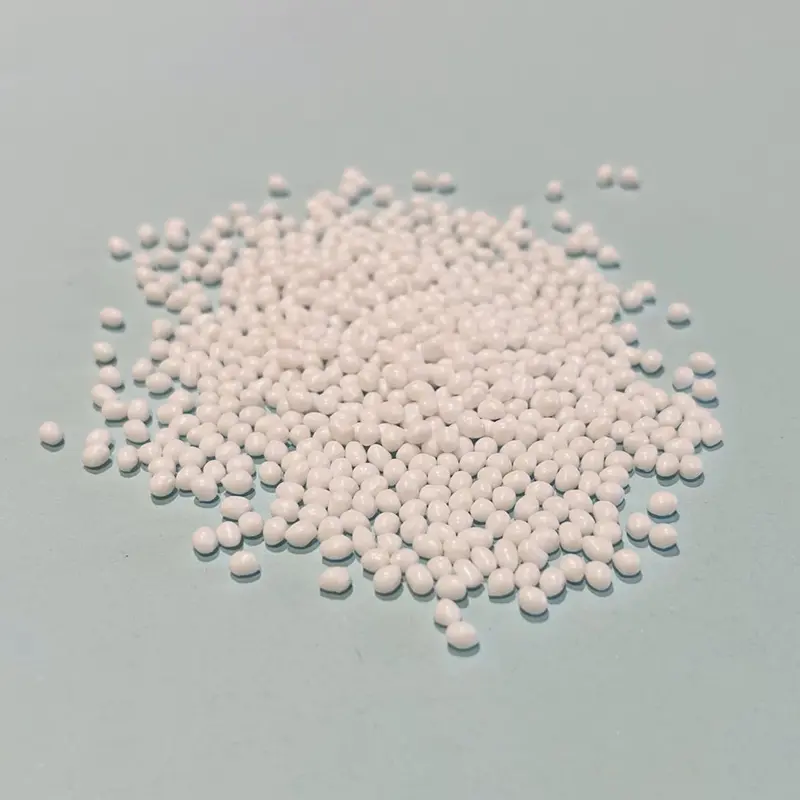

PET mankhwala dzina Polyethylene terephthalate, amadziwikanso kuti poliyesitala, mankhwala chilinganizo COC6H4COOCH2CH2O.Dihydroxyethyl terephthalate linakonzedwa ndi transesterification wa dimethyl terephthalate ndi ethylene glycol kapena esterification wa terephthalate ndi ethylene glycol, ndiyeno polycondensation anachita.Ndi crystalline saturated poliyesitala, yoyera yamkaka kapena yopepuka yachikasu, polima yowala kwambiri yokhala ndi pamwamba komanso yonyezimira.Ndi utomoni wamba m'moyo ndipo akhoza kugawidwa mu APET, RPET ndi PETG.

PET ndi yoyera yamkaka kapena yachikasu chopepuka, yowoneka bwino kwambiri komanso yosalala komanso yonyezimira.Ili ndi zinthu zabwino kwambiri zakuthupi komanso zamakina pa kutentha kwakukulu, kutentha kwanthawi yayitali mpaka 120 ℃, kutchinjiriza kwamagetsi kwabwino kwambiri, ngakhale kutentha kwambiri komanso pafupipafupi, magetsi ake akadali abwino, koma kukana koyipa kwa corona, kukana kukwawa, kukana kutopa, kukana kukangana, kukhazikika kwazithunzi ndizabwino kwambiri.PET ili ndi mgwirizano wa ester, kuwonongeka kudzachitika pansi pa zochita za asidi amphamvu, alkali wamphamvu ndi nthunzi yamadzi, kukana zosungunulira organic, kukana kwanyengo.

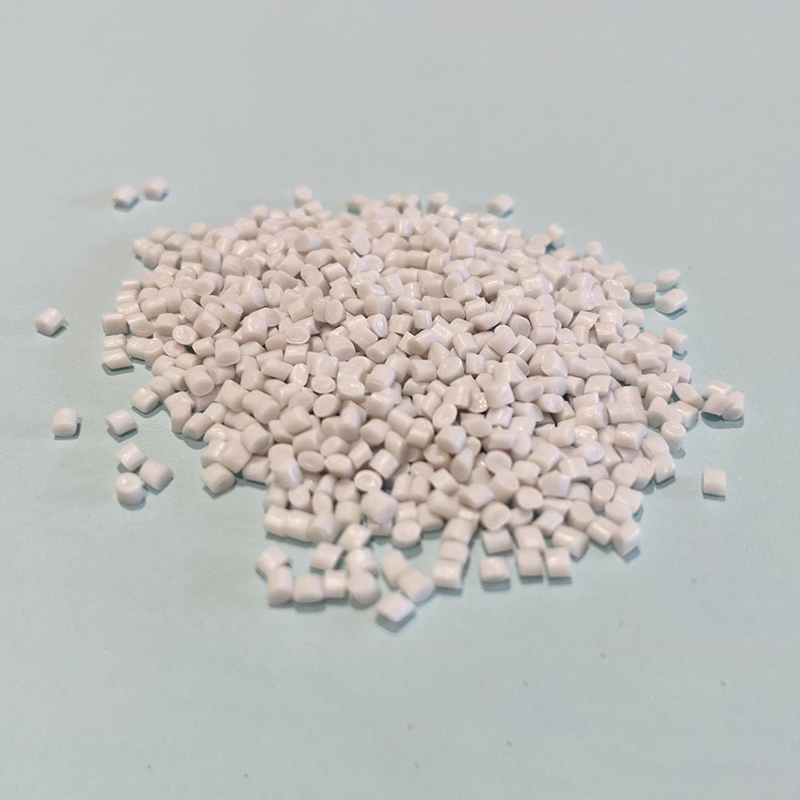

2.resin katundu

PET ili ndi kukana kwabwino, kukana kutopa, kukana kukangana ndi kukhazikika kwa mawonekedwe, kuvala pang'ono komanso kulimba kwambiri, ndipo imakhala yolimba kwambiri mu thermoplastics: kuyendetsa bwino kwamagetsi kwamagetsi, kutengera pang'ono kutentha, koma kusalimba kwa corona.Zopanda poizoni, kukana nyengo, kukhazikika kwabwino motsutsana ndi mankhwala, kuyamwa kwamadzi otsika, kukana ma acid ofooka ndi zosungunulira za organic, koma osati kumizidwa m'madzi osamva kutentha, osati kukana kwa alkali.

PET utomoniali ndi kutentha kwa magalasi apamwamba, kusinthasintha kwapang'onopang'ono, kuzungulira kwautali, kuzungulira kwautali, kupukuta kwakukulu, kupukuta kwakukulu, kusasunthika kosaoneka bwino, brittle crystallization akamaumba, kukana kutentha kochepa.

Kupyolera mu kukonza kwa nucleating agents ndi crystallizing agents ndi galasi fiber reinforcement, PET ili ndi zotsatirazi kuwonjezera pa katundu wa PBT.

1. Kutentha kwa kutentha kwa kutentha ndi kutentha kwa nthawi yayitali ndizomwe zimakhala zapamwamba kwambiri mu mapulasitiki a engineering thermoplastic general engineering.

2. Chifukwa cha kukana kutentha kwakukulu, PET yowonjezera imayikidwa kwa 10S mu bafa ya solder pa 250 ° C, pafupifupi popanda mapindikidwe kapena kusinthika, komwe kuli koyenera kwambiri pokonzekera mbali zamagetsi ndi zamagetsi zowotcherera.

3. Mphamvu yopindika ndi 200MPa, zotanuka modulus ndi 4000MPa, kukana kukwawa ndi kutopa kulinso kwabwino kwambiri, kuuma kwa pamwamba ndikwambiri, ndipo zida zamakina ndizofanana ndi mapulasitiki a thermosetting.

4. Popeza mtengo wa ethylene glycol wogwiritsidwa ntchito popanga PET ndi pafupifupi theka la butanediol lomwe limagwiritsidwa ntchito popanga PBT, PET resin ndi PET reinforced ndi mtengo wotsika kwambiri pakati pa mapulasitiki a engineering ndipo ali ndi ntchito yotsika mtengo.

Kuwongolera katundu wa PET, PET imatha kuphatikizidwa ndi PC, elastomer, PBT, kalasi ya PS, ABS, PA.

PET (yowonjezera PET) imagwiritsidwa ntchito makamaka ndi jekeseni, ndipo njira zina zimaphatikizapo extrusion, kuwombera, kupaka ndi kuwotcherera, kusindikiza, machining, kupaka vacuum ndi njira zina zothandizira.Yanikani bwino musanapange.

Polyethylene terephthalate amakonzedwa ndi transesterification wa dimethyl terephthalate ndi ethylene glycol kapena esterification wa terephthalate ndi ethylene glycol, ndiyeno polycondensation anachita.Ndi crystalline zimalimbikitsa poliyesitala, pafupifupi molekyulu kulemera (2-3) × 104, chiŵerengero cha kulemera pafupifupi kwa chiwerengero pafupifupi maselo kulemera ndi 1.5-1.8.

Galasi kusintha kutentha 80 ℃, Martin kutentha kukana 80 ℃, matenthedwe kutentha kutentha 98 ℃ (1.82MPa), kuwonongeka kutentha 353 ℃.Ili ndi zida zabwino zamakina.Kukhazikika kwakukulu.Kuuma kwakukulu, kuyamwa kwamadzi pang'ono, kukhazikika bwino kwa mawonekedwe.Kulimba kwabwino, kukana kwamphamvu, kukana kukangana, kukana kugwa.Good chemical resistance, sungunuka mu cresol, concentrated sulfuric acid, nitrobenzene, trichloroacetic acid, chlorophenol, insoluble mu methanol, ethanol, acetone, alkane.Kutentha kwa ntchito -100 ~ 120 ℃.Mphamvu yopindika 148-310MPa

Mayamwidwe amadzi 0.06% -0.129%

Mphamvu yamphamvu 66.1-128J / m

Rockwell kuuma M 90-95

Elongation 1.8% -2.7%

3. luso processing

Kukonza kwa PET kumatha kukhala jekeseni, extrusion, kuwombera, kupaka, kumanga, machining, electroplating, vacuum plating golide, kusindikiza.Zotsatirazi zikuwonetsa mitundu iwiri.

1. jekeseni siteji ① kutentha kutentha: nozzle: 280 ~ 295 ℃, kutsogolo 270 ~ 275 ℃, pakati forging 265 ~ 275 ℃, pambuyo 250-270 ℃;Screw liwiro 50 ~ 100rpm, nkhungu kutentha 30 ~ 85 ℃, nkhungu amorphous ndi 70 ℃, kuthamanga kumbuyo 5-15KG.② Mayesero dehumidification chowumitsira, zinthu chubu kutentha 240 ~ 280 ℃, jekeseni kuthamanga 500 ~ 1400 ℃, jekeseni akamaumba kutentha 260 ~ 280 ℃, kuyanika kutentha 120 ~ 140 ℃, kutenga 2 ~ 5 maola.

2. Mufilimuyi, utomoni wa PET umadulidwa ndikuwumitsidwa kale kuti uteteze hydrolysis, ndiyeno pepala lakuda la amorphous limatulutsidwa mu extruder pa 280 ° C kupyolera mu T-mold, ndipo ng'oma yozizira kapena ozizira amazimitsidwa. isungeni mu mawonekedwe aamorphous kuti ikhale yokhazikika.Tsamba lokhuthala limatambasulidwa ndi tenter kuti lipange filimu ya PET.

Longitudinal kutambasula ndi preheat pepala wandiweyani kuti 86 ~ 87 ℃, ndipo pa kutentha, Tambasula pafupifupi 3 zina pamodzi ndi malangizo utali wa ndege wandiweyani pepala, kuti lathu akhoza kusintha mlingo wa crystallization kufika kutentha apamwamba: the transverse preheating kutentha kwa 98 ~ 100 ℃, kutentha kwamphamvu kwa 100 ~ 120 ℃, ma tensile chiŵerengero cha 2.5 ~ 4.0, ndi kutentha kwa kutentha kwa 230 ~ 240 ℃.Firimuyi itatha kutambasula molunjika ndi yopingasa iyeneranso kukhala yotentha kuti ithetse kusinthika kwa filimu chifukwa cha kutambasula ndikupanga filimu yokhala ndi kukhazikika kwabwino kwa kutentha.

Nthawi yotumiza: Sep-05-2023